From Waze to cancer-busting nano-ghost cells and 3-D printed hearts, The Times of Israel takes a dive into tech that helps us get where we’re going and keeps us safe and healthy

Article published at www.timesofisrael.com on January 1, 2020.

The Beresheet selfie during landing, April 11, 2019. (YouTube screenshot)

The Beresheet selfie during landing, April 11, 2019. (YouTube screenshot)

As we enter 2020, The Times of Israel has taken a look at some of the coolest Israeli technologies and inventions of the past 10 years — those that are already hugely impacting the way we live and those that have the potential of changing our lives and health.

The list is of course purely subjective, and there are so many other Israeli technologies and startups out there that are making a difference to our world.

Driving with your personal navigator: Waze

This GPS navigation software works on smartphones or car screens, providing turn-by-turn information to drivers about how best to get to their destination, including estimated length of travel and time of arrival.

The software has revolutionized how people drive: like old-school GPS systems, it does away with printed maps and recalculates if you make a mistake, but this unflappable piece of software also smoothly updates its instructions based on real-time conditions and bases its advice partly on user input relating to traffic jams and other road pitfalls.

Waze navigation screen (photo credit: Courtesy)

Waze navigation screen (photo credit: Courtesy)

The technology was developed by Israeli founders Ehud Shabtai, Amir Shinar and Uri Levine and was snapped up by US tech giant Google in 2013 for some $1 billion.

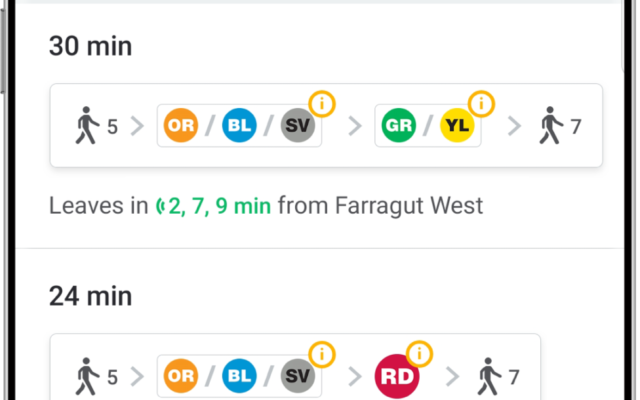

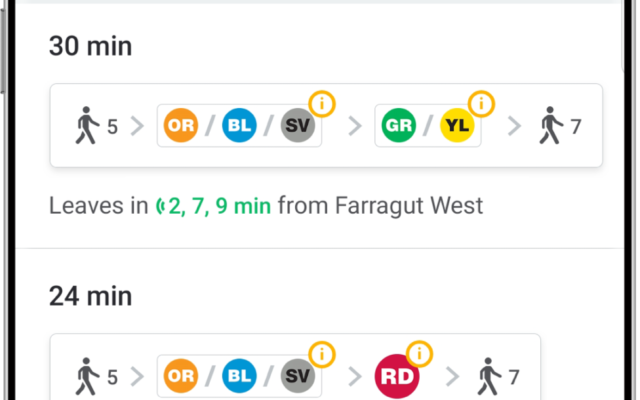

Using public transportation better: Moovit

This smartphone app allows users to find the best way to their destination using public transportation, and the Israeli startup by the same name this summer hit a milestone of over half a billion users around the world. Moovit, founded in 2012 by entrepreneurs Nir Erez, Roy Bick, and Yaron Evron and headquartered in Ness Ziona, has been referred to as the “Waze for public transportation.”

The Moovit app in use in Washington, US (Courtesy)

The Moovit app in use in Washington, US (Courtesy)

The free crowdsourced app provides real-time bus, train, subway, and light rail schedules, offers route options to help users find the quickest, most efficient way to their destinations, and issues exact instructions on how to get there.

The firm has raised some $131.5 million to date from investors including Intel Capital, the investment arm of Intel Corp., Sequoia Capital Israel, BMW i Ventures, and NGP Capital, a VC firm based in Palo Alto, California.

Water from thin air: Watergen

This startup creates drinking water by capturing the humidity from the air. It was set up in 2010 by Arye Kohavi, a former combat reconnaissance company commander in the Israel Defense Forces.

Drawing water from a Watergen generator in Bukhara, Uzbekistan. (Screenshot/YouTube )

Drawing water from a Watergen generator in Bukhara, Uzbekistan. (Screenshot/YouTube )

The water-making machine uses a series of filters to purify the air. After the air is sucked in and chilled to extract its humidity, the water that forms is treated and transformed into clean drinking water. The technology uses a plastic heat exchanger rather than an aluminium one, which helps reduce costs; it also includes proprietary software that operates the devices.

Did we get all of the cancer out? Dune Medical Devices

The startup developed the MarginProbe device to help surgeons find out, on the spot, if they have removed all of the cancerous tissue or not, thus helping women with breast cancer avoid undergoing dreaded follow-up surgery to remove residual cancer cells after a tumour is excised. The device has shown to reduce re-excisions in breast-conserving surgery by over 50% and has been used in over 20,000 procedures in hospitals in the US and in Israel, according to the firm.

Dune Medical’s MarginProbe reduces amount of follow-up breast cancer surgery (Courtesy)

Dune Medical’s MarginProbe reduces amount of follow-up breast cancer surgery (Courtesy)

The startup was founded in 2002 by Dr. Dan Hashimshony.

Shooting rockets out of the sky: The Iron Dome missile system

The Iron Dome is an air defence system developed by Rafael Advanced Defense Systems and Israel Aerospace Industries. Using advanced radar and software, this device, which predicts an incoming rocket’s trajectory and shoots it out of the sky, has helped save lives in Israel during rocket attacks from the Gaza Strip. The system was initially deployed in 2011 near Beersheba, where it successfully intercepted its first rocket. Brigadier General Danny Gold and Chanoch Levine were behind the development of the system.

An Israeli missile launched from the Iron Dome defence missile system, designed to intercept and destroy incoming short-range rockets and artillery shells, in the southern Israeli city of Sderot, on November 12, 2019. (MENAHEM KAHANA / AFP)

An Israeli missile launched from the Iron Dome defence missile system, designed to intercept and destroy incoming short-range rockets and artillery shells, in the southern Israeli city of Sderot, on November 12, 2019. (MENAHEM KAHANA / AFP)

Helping those with paralysis to walk: ReWalk Robotics

This Israeli firm has developed the ReWalk “exoskeleton system” that enables people who are paralyzed to walk by letting computers and motion sensors do all of the “heavy lifting” of the body. The system controls movement using subtle changes in the center of gravity mimics natural gait and provides a functional walking speed, enabling people who are paralyzed to stand up straight again, walk down the aisle with their loved one and even run marathons.

With the help of ReWalk Robotics, Dudu Shevy is able to walk down the aisle (screen capture: Channel 2)

With the help of ReWalk Robotics, Dudu Shevy is able to walk down the aisle (screen capture: Channel 2)

ReWalk Robotics is a Nasdaq-traded Israeli company. The inventor of the system, Amit Goffer, is a mechanical engineer who became paralyzed from his upper back down after an accident.

Helping the blind ‘see’: OrCam

This Israeli startup develops products based on advanced computerized visual interpretation capabilities. The firm’s artificial vision wireless product is basically a miniature camera attached to a computing device, less than an ounce in weight and the size of a finger, with a personal speaker on the other end.

OrCam’s MyEye 2 can recognize text from any surface (Courtesy)

OrCam’s MyEye 2 can recognize text from any surface (Courtesy)

When the OrCam camera is attached to the frame of a pair of glasses, users can point to text on any surface, and the speaker transforms the image into words and reads them out. That way, users can “read” newspapers, restaurant menus, or books — even ballot slips. The AI-driven software uses the high-resolution video camera and smart algorithms that analyze what the camera is seeing, and reads back the information to a user in real-time.

Ziv Aviram, the CEO and co-founder of the Jerusalem-based startup, set up the firm in 2010 together with Prof. Amnon Shashua. The two entrepreneurs are also the founders of Mobileye, a maker of self-driving car technologies, acquired in 2017 by Intel Corp. for a massive $15.3 billion.

Have a heart: The 3D-printed heart

Scientists at Tel Aviv University unveiled a 3D print of a heart with human tissue and vessels earlier this year, calling it a “major medical breakthrough” that advances possibilities for transplants.

Professor Tal Dvir presents a 3D print of a heart with human tissue at Tel Aviv University on April 15, 2019. (Jack Guez/AFP)

Professor Tal Dvir presents a 3D print of a heart with human tissue at Tel Aviv University on April 15, 2019. (Jack Guez/AFP)

While it still remains a far way off, the scientists hope one day to be able to produce hearts suitable for transplant into humans as well as patches to regenerate defective hearts.

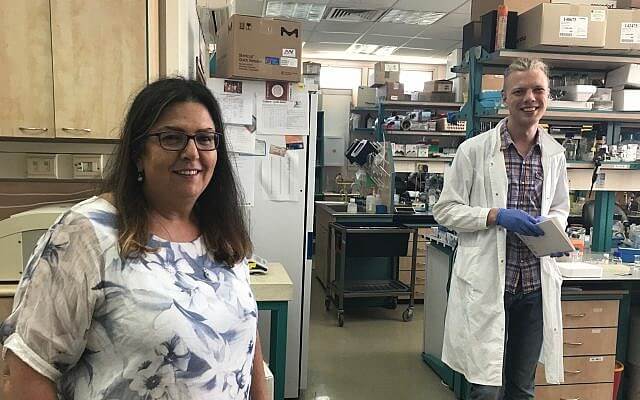

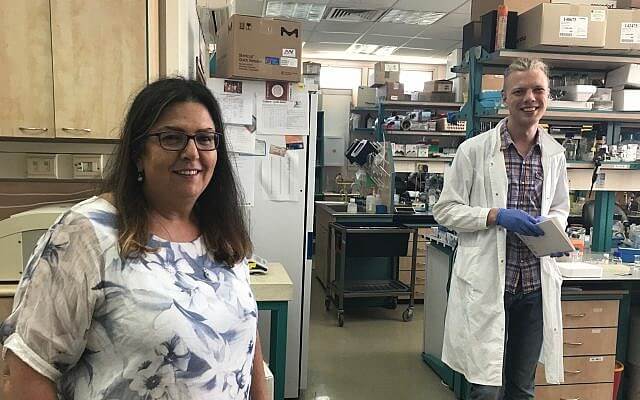

Ghost cells that target cancer: NanoGhost

NanoGhost is a startup set up by Prof. Marcelle Machluf that aims to shrink the deadliest forms of cancer by precisely targeting tumours. Machluf developed the technology in her lab at the Technion-Israel Institute of Technology, and she has now set up a startup as a spin-off from the university to commercialize the technology. The startup got funding earlier this month from the moon venture capital fund.

In their work, Machluf and her team at the Technion used mesenchymal stem cells — cells, found in all humans, that play multiple roles in the body, differentiating into a variety of cell types. These cells help cancerous cells hide from the immune system, allowing the cancers to thrive and grow to a size that makes it impossible for the immune system to later attack.

The Technion’s Prof. Marcelle Machluf, left, at her lab in Haifa with a lab assistant; June 19, 2019 (Shoshanna Solomon/Times of Israel)

The Technion’s Prof. Marcelle Machluf, left, at her lab in Haifa with a lab assistant; June 19, 2019 (Shoshanna Solomon/Times of Israel)

Machluf’s team took these cells and emptied them of their content — creating “ghost-like” cells — and then reconstructed them into nano-vehicles filled with anti-cancer drugs. These are then injected into the bloodstream and released directly into the tumours. Animal experiments have shown that NanoGhosts may reduce tumour size in small lung carcinoma, prostate, and pancreatic cancer tumours by as much as 85%, the company said.

And what does your gut say? DayTwo

The DayTwo startup has developed an app that provides customized nutrition recommendations based on an analysis of gut bacteria, with the aim of helping diabetes patients find the best foods for them to avoid sugar spikes.

Users of the service get a home kit through which they send a sample of their stool by courier to a lab, where their gut bacteria’s genetic profile is analyzed. Patients also fill out a medical questionnaire and provide blood test results. They then get a personalized diet with recommendations for menus that best suit their gut.

The DayTwo app in action (Courtesy)

The DayTwo app in action (Courtesy)

DayTwo was founded in 2015 by entrepreneur Marius Nacht, who is also the founder of Israeli cybersecurity firm Check Point Software Technologies Ltd., chairman Yuval Ofek, CEO Lihi Segal, and managing partner Yair Schindel.

The company’s technology is based on research developed at the Weizmann Institute of Science. The researchers genetically sequenced the DNA of all of the bacteria of the gut and then created multiple profiles of people based on their bacteria. Their study showed that different people eating the same foods can have different sugar — or glycemic — responses, depending on the kind of gut bacteria they have.

Shooting for the Moon: Beresheet, by SpaceIL

Beresheet was an Israeli spacecraft that never managed to land on the moon, crashing on it instead, but was a winner anyway because of the chutzpah and daring it represented. Had the landing succeeded, it would have made Israel the fourth country, with the first privately owned spacecraft, to land on the moon.

Yariv Bash, right, Yonatan Winetraub, middle, and Kfir Damari, the founders of SpaceIL, inserting a digital time capsule into the Beresheet spacecraft, December 17, 2018. (Yoav Weiss)

Yariv Bash, right, Yonatan Winetraub, middle, and Kfir Damari, the founders of SpaceIL, inserting a digital time capsule into the Beresheet spacecraft, December 17, 2018. (Yoav Weiss)

“We are on the moon, but not in the way that we wanted to,” operational control director Alex Fridman said grimly to engineers in the control room after the spacecraft crashed on the moon in April this year.

The spacecraft, roughly the size of a compact car, was budgeted at fraction of the cost of vehicles launched to the moon by major powers the US, Russia and China in the past.

It was a crazy idea that was hatched by three friends at a bar in Holon, Yonatan Winetraub, Kfir Damari and Yariv Bash, who set up the SpaceIL startup to propel their moon-landing dream. Together they somehow collected $100 million in donations, harnessed a team of dozens of engineers, and captured the attention and dreams of Israel and the world.

Sir Winston Churchill

Sir Winston Churchill

The Churchill Building at Technion – Israel Institute of Technology in Haifa

The Churchill Building at Technion – Israel Institute of Technology in Haifa

Photo by Ben Kelmer courtesy British Embassy Israel

Photo by Ben Kelmer courtesy British Embassy Israel Photo by Ben Kelmer courtesy British Embassy Israel

Photo by Ben Kelmer courtesy British Embassy Israel

Waze navigation screen (photo credit: Courtesy)

Waze navigation screen (photo credit: Courtesy) The Moovit app in use in Washington, US (Courtesy)

The Moovit app in use in Washington, US (Courtesy) Drawing water from a Watergen generator in Bukhara, Uzbekistan. (Screenshot/YouTube )

Drawing water from a Watergen generator in Bukhara, Uzbekistan. (Screenshot/YouTube ) Dune Medical’s MarginProbe reduces amount of follow-up breast cancer surgery (Courtesy)

Dune Medical’s MarginProbe reduces amount of follow-up breast cancer surgery (Courtesy) An Israeli missile launched from the Iron Dome defence missile system, designed to intercept and destroy incoming short-range rockets and artillery shells, in the southern Israeli city of Sderot, on November 12, 2019. (MENAHEM KAHANA / AFP)

An Israeli missile launched from the Iron Dome defence missile system, designed to intercept and destroy incoming short-range rockets and artillery shells, in the southern Israeli city of Sderot, on November 12, 2019. (MENAHEM KAHANA / AFP) With the help of ReWalk Robotics, Dudu Shevy is able to walk down the aisle (screen capture: Channel 2)

With the help of ReWalk Robotics, Dudu Shevy is able to walk down the aisle (screen capture: Channel 2) OrCam’s MyEye 2 can recognize text from any surface (Courtesy)

OrCam’s MyEye 2 can recognize text from any surface (Courtesy) Professor Tal Dvir presents a 3D print of a heart with human tissue at Tel Aviv University on April 15, 2019. (Jack Guez/AFP)

Professor Tal Dvir presents a 3D print of a heart with human tissue at Tel Aviv University on April 15, 2019. (Jack Guez/AFP) The Technion’s Prof. Marcelle Machluf, left, at her lab in Haifa with a lab assistant; June 19, 2019 (Shoshanna Solomon/Times of Israel)

The Technion’s Prof. Marcelle Machluf, left, at her lab in Haifa with a lab assistant; June 19, 2019 (Shoshanna Solomon/Times of Israel) The DayTwo app in action (Courtesy)

The DayTwo app in action (Courtesy) Yariv Bash, right, Yonatan Winetraub, middle, and Kfir Damari, the founders of SpaceIL, inserting a digital time capsule into the Beresheet spacecraft, December 17, 2018. (Yoav Weiss)

Yariv Bash, right, Yonatan Winetraub, middle, and Kfir Damari, the founders of SpaceIL, inserting a digital time capsule into the Beresheet spacecraft, December 17, 2018. (Yoav Weiss)

Ph.D. Student Michal Rosenberg

Ph.D. Student Michal Rosenberg Cover of the November 6, 2019 issue of Small, dedicated to the research of Prof. Ester Segal. Silicon chips are inserted into the brain of a mouse by safe implantation or with a gene gun. The chips break down while releasing a neural growth factor, a protein that prevents the death of nerve cells in Alzheimer’s disease. (credit: Ella Maru Studio)

Cover of the November 6, 2019 issue of Small, dedicated to the research of Prof. Ester Segal. Silicon chips are inserted into the brain of a mouse by safe implantation or with a gene gun. The chips break down while releasing a neural growth factor, a protein that prevents the death of nerve cells in Alzheimer’s disease. (credit: Ella Maru Studio)

Technion students faced with challenges of entrepreneurship at the Technion, December 19, 2019. (Courtesy)

Technion students faced with challenges of entrepreneurship at the Technion, December 19, 2019. (Courtesy) Former Intel Israel President Mooli Eden, left to right; Lena Levine, the co-founder of Via Surgical; Yossi Vardi; Gal Haber, co-founder and managing director of Plus500 Ltd; Dov Moran speak in a panel at entrepreneurship day at the Technion Dec. 19, 2019 (Courtesy)

Former Intel Israel President Mooli Eden, left to right; Lena Levine, the co-founder of Via Surgical; Yossi Vardi; Gal Haber, co-founder and managing director of Plus500 Ltd; Dov Moran speak in a panel at entrepreneurship day at the Technion Dec. 19, 2019 (Courtesy) Ezri Tarazi, professor of industrial design in charge of the t-hub entrepreneurship program of the Technion, December 19, 2019. (Shoshanna Solomon/Times of Israel)

Ezri Tarazi, professor of industrial design in charge of the t-hub entrepreneurship program of the Technion, December 19, 2019. (Shoshanna Solomon/Times of Israel) Technion students taking a break on the grass on a sunny winter day when entrepreneurs flocked to the Haifa campus to talk to students, December 19, 2019. (Shoshanna Solomon/Times of Israel)

Technion students taking a break on the grass on a sunny winter day when entrepreneurs flocked to the Haifa campus to talk to students, December 19, 2019. (Shoshanna Solomon/Times of Israel) The hackathon about behavioral economics held by Dan Arieli at the Technion, December 22, 2019. (Courtesy)

The hackathon about behavioral economics held by Dan Arieli at the Technion, December 22, 2019. (Courtesy) Luna Karayanni, a 20-year-old second-year computer sciences student at the Technion, left, together with Mais Haddad, her 20-year old friend, who studies bio-medical engineering, and Sabri Asssaf, a 20-year-old bioengineering student, at the Technion campus in Haifa’ December 19, 2019. (Shoshanna Solomon/Times of Israel)

Luna Karayanni, a 20-year-old second-year computer sciences student at the Technion, left, together with Mais Haddad, her 20-year old friend, who studies bio-medical engineering, and Sabri Asssaf, a 20-year-old bioengineering student, at the Technion campus in Haifa’ December 19, 2019. (Shoshanna Solomon/Times of Israel)

Left: Atomic structure of a segment from a protein that forms fibrils that structure the biofilm of E. coli and Salmonella bacteria. This structure is highly similar to that of the amyloid fibrils related to Alzheimer’s disease, and this structural similarity inspired the idea of harming the bacterial biofilm fibrils using substances developed to combat Alzheimer’s fibrils. Top (black and white): Micrographs taken with an electron microscope. The left image shows fibrils produced by bacterial proteins that serve to build the biofilm; the right image shows impairment in the formation of the fibrils as a result of adding the substance developed to combat Alzheimer fibrils (ANK6). Bottom (black and red): Three-dimensional images taken by a confocal laser scanning microscope after coloring the bacterial biofilm in fluorescent red. Left: High biofilm biomass. Right: Addition of ANK6 leads to a significant decrease in the amount of biofilm.

Left: Atomic structure of a segment from a protein that forms fibrils that structure the biofilm of E. coli and Salmonella bacteria. This structure is highly similar to that of the amyloid fibrils related to Alzheimer’s disease, and this structural similarity inspired the idea of harming the bacterial biofilm fibrils using substances developed to combat Alzheimer’s fibrils. Top (black and white): Micrographs taken with an electron microscope. The left image shows fibrils produced by bacterial proteins that serve to build the biofilm; the right image shows impairment in the formation of the fibrils as a result of adding the substance developed to combat Alzheimer fibrils (ANK6). Bottom (black and red): Three-dimensional images taken by a confocal laser scanning microscope after coloring the bacterial biofilm in fluorescent red. Left: High biofilm biomass. Right: Addition of ANK6 leads to a significant decrease in the amount of biofilm.