Robots have captured the imaginations – and often raised the fears – of people for at least a century. These programmable machines perform boring, repetitive and dangerous tasks that people prefer not to or are unable to do because of size limitations or because they function in extreme environments such as in outer space or at the bottom of the sea.

The term comes from a Slavic root, robot-, with meanings connected to the word “labor” and was first used to denote a fictional humanoid in a Czech-language play R.U.R. (Rossumovi Univerzální Roboti – Rossum’s Universal Robots) written 101 years ago by Karel Čapek, (although it was apparently Karel’s brother Josef who first gave the concept a name).

A robot may be guided by an externally controlled device or the control may be embedded inside its body. Robots can be constructed to look like humans or even dogs, but most robots are functional machines that perform tasks efficiently and thus designed without much attention to aesthetics.

They can be programmed to function autonomously or semi-autonomously and include humanoids such as Honda’s ASIMO (Advanced Step in Innovative Mobility) – the apex of 20 years of robotics research that can run, walk on uneven slopes and surfaces, climb stairs, turn smoothly, reach for and grasp objects and even understand and respond to simple voice commands. Robots are beginning to assist in hospitals, take hotel guests to their rooms, accept and deliver food orders and carry out numerous other tasks. But more common are industrial robots that build cars and perform other manufacturing work in factories, medical operating robots, high-flying drones that observe and even attack enemies, patient-assist robots and dog therapy robots that assist and reduce loneliness among the elderly and the disabled.

The 1966 American science fiction movie Fantastic Voyage about a submarine crew who are shrunk to microscopic size and float inside the body of an injured scientist to repair damage to his brain even presaged microscopic nano robots that today are hinting that they are no longer science fiction.

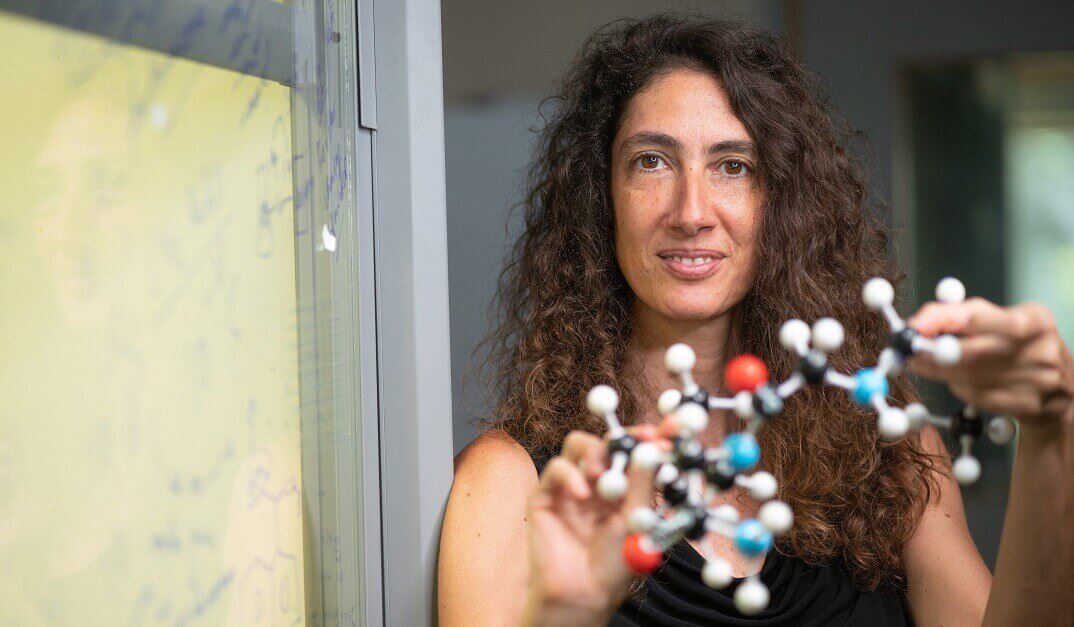

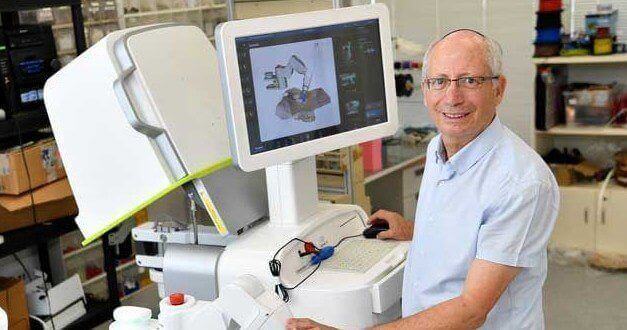

One of the world’s leaders in medical robots – the founder of numerous companies, the inventor with more than 100 individual patents publisher of more than 200 technical papers and three books and the teacher who has inspired many young people in Israel and around the world to enter the field – is Emeritus Prof. Moshe Shoham, who was born in Haifa. His official title is bearer of the Tamara and Harry Handelsman Academic Chair and director of the robotic laboratory in the department of mechanical engineering at the Technion – Israel Institute of Technology

in Haifa.

In 1978, Shoham earned his bachelor of science degree from the Technion in in the Faculty of Aeronautical Engineering, worked in Israel Aerospace Industries followed four years later by a master’s degree from its Faculty of Mechanical Engineering and a doctorate in 1986 from that same faculty. His main professional interests are robotic systems (kinematics and dynamics of robots), multi-fingered hands, sensor-based robots and medical robotics.

There were no approved medical robots in the world when he began. The pioneer in this area was a company named ISS, which developed a robot for replacing the hip joint, thereby opening the market, but eventually it failed to obtain approval from the US Food and Drug Administration (FDA). The company closed down in 2005, exactly when Shoham’s company, Mazor Robotics Ltd., got its marketing approval. In 2001, he founded Mazor, which was acquired in 2018 by the global medical electronics company Medtronic for $1.64 billion.

After working in the Israel Aerospace Industries, Shoham served as an assistant professor at Columbia University in New York and established the robotic laboratory at the department of mechanical engineering, a visiting professor at Stanford University in California. He is also a Fellow of the Institute of Electrical and Electronics Engineers (IEEE) Fellow of the American Society of Mechanical Engineers (ASME) and a International Member of the US National Academy of Engineering,

Among his numerous awards, are honorary membership – Israel Society for Medical and Biological Engineering, 2020; the Maurice E. Müller Award for Excellence in Computer Assisted Surgery, 2019; Innovation Award – Surgical Robot Challenge, Imperial College, London, 2016; Fellow –Institute of Electrical and Electronics Engineers (IEEE), 2015; International Member – US National Academy of Engineering, 2014; Thomas A. Edison Patent Award – American Society of Mechanical Engineers, 2013; Hershel Rich Innovation Award, 2011; Technology Award – the Society for Medical Innovation and Technology (SMIT), 2008; Fellow – The American Society of Mechanical Engineers (ASME), 2008; Outstanding Israeli project – ROBOCAST: ROBOt and sensors integration for Computer Assisted Surgery and Therapy, European Union 7th Framework Program for Research and Technological Development. Awarded by the European Commission to the State of Israel, 2007; Kaplan Prize for Creative Management of High Technology, 2002; and the Juludan Award for Outstanding Scientific Research Achievements, 1999. Shoham is particularly proud of the recent 2021 Yigal Allon Prize for Pioneering Excellence – given annually to individuals, entities or organizations whose activity serves as a model of pioneering excellence and a significant contribution to Israeli society – that he received recently.

The 2021 prize was awarded jointly to Shoham and Start-Up Nation Central for their work in promoting Israeli innovation in industry. “The entire state of Israel walks in your path,” Israel’s President Isaac Herzog said in congratulatory remarks.

Among the most memorable and thought-provoking award for Shoham was in 1999, when he received a research award for the development of a robot that performs knee replacement surgery with great precision.

“Next to me, Prof. Gershon Golomb from the Hebrew University of Jerusalem’s Faculty of Medicine also received the award. The winners’ families were invited to the award ceremony. At the entrance to the hall, I saw and was shocked that instead of coming to me, my mother fell into the arms of the mother of Prof. Golomb whom I did not know and burst into tears. When they stopped crying, my mother told me that Golomb’s mother shared with her a wooden bunk in the Auschwitz concentration camp during the Holocaust. They encouraged and strengthened each other during all that terrible time.”

This moving event “made me wonder: how many more people could have received the prize but did not because they were murdered in the Holocaust.” Among them were potential writers, poets, musicians, scientists, rabbis, actors, geniuses, shoemakers, carpenters, tanners. “How many worlds will no longer be created, and why?!”

Indeed, if the mothers of Prof. Shoham and Prof. Golomb had (God forbid) perished in the gas chambers of Auschwitz, their sons would never had been born and their great healing and lifesaving accomplishments would have been lost to the world.

Shoham’s father was born in Romania and escaped from Europe during the Nazi era, fortunately moving to Israel, where he settled in the youth village and agricultural settlement of Mikve Yisrael and helped establish a kibbutz called Tehiya. His mother was born in Czechoslovakia, and after being liberated from the concentration camp, moved to Palestine where she met her future husband at the kibbutz.

Moshe, who recalls that his family lived in modest circumstances, liked from boyhood to build and fix things. That hobby led to his outstanding mechanical engineering career.

Today, he and his wife live in Hoshaya, a national-religious community settlement in the Lower Galilee. The village was established in three decades ago as a Nahal settlement, originally planned for soldiers from moshavim in the Galilee and later manned by soldier of the Religious Nahal Youth Aliyah, Three years later, it was transferred to civilians, and 15 families moved into caravans on the site, with some of the original Nahal soldiers remaining.

At Stanford, Shoham began to think about developing medical robots, which were then in their infancy. “I returned to Israel and called surgeons in all the hospitals. Even though medicine is very conservative, some of them were very supportive of the idea,” he recalled in an interview. “Some were opposed to the use of robots in surgery, and a few of them said it will not work and no robot would ever replace a human surgeon.” “we would like to apply robots at those tasks in which robots excel – accuracy and accessibility – but the decision making will always remain with the surgeon.”

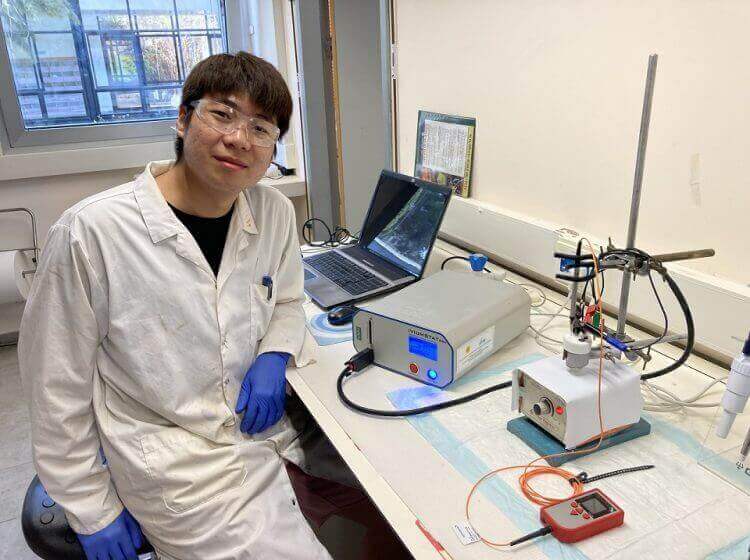

Shoham established Mazor Robotic company, specializing in spinal surgery. Shoham founded a number of companies, each with a robotic surgery specialty. One company that is based on technology developed in his medical robotic laboratory donated by the late Betty and Dan Kahn, is Xact robotics, which has developed a robot for precise navigating of flexible needle within the body. This technology is suitable for a variety of types of operations requiring penetration by a narrow instrument to a precise point deep within the body, such as biopsies, injections of drugs into internal organs, ablation (precise searing of tissue within the body) and drainage from within the body.

Another company he founded, Diagnostic Robotics, aims at dramatically reducing the time spent in emergency rooms. Shoham does not discuss what this robot can do, so it is possible that it can already perform several physical examinations even before the doctor.

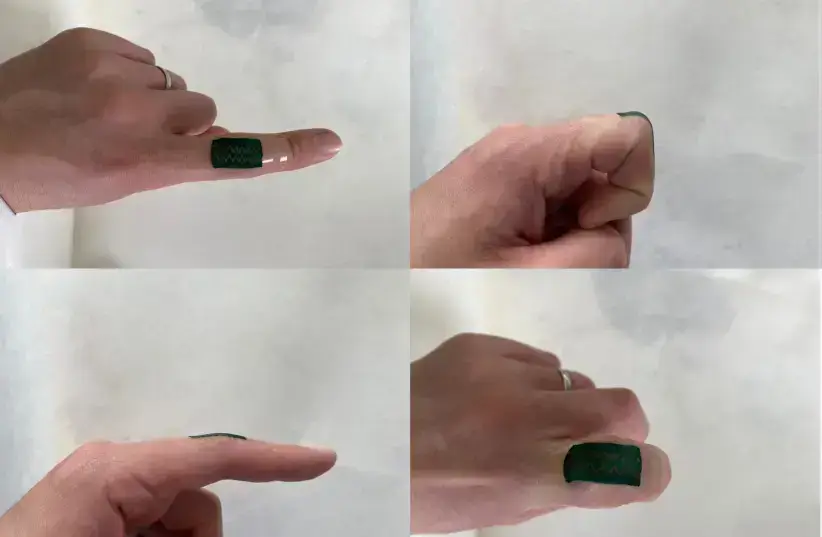

ForSight Robotics is developing a surgical robotic platform for eye surgery to assist ophthalmologists. Microbot Medical (a company listed on Nasdaq as MBOT) that he co-founded has developed a system that includes miniature robots for internal cleaning of an implanted medical device, including devices implanted in the brain. His Microbot ViRob, an autonomous advancing micro robot – less than one millimeter in diameter, has the ability to crawl within cavities and lumens, allowing physicians to target a disease site with amazing precision.

So far, the device has completed animal trials; in the future, the product is likely to also prove suitable for cleaning blood vessels so as prevent heart attacks and strokes.

A company based on his doctoral student Hadas Ziso’s thesis is Tamar Robotics, which is developing a surgical robot for revolutionizing brain surgery, finally giving doctors a safer, minimally invasive tool to remove tumors and blood clots and treat other life-threatening brain conditions that now require major surgery.

“We hope we will be able to let the people suffering from these conditions get back to their lives,” Shoham says. “We believe that our robotic system is additional outstanding armament in the surgeon’s hand that can be used at those instances they perform better than a surgeon’s free hand.” The neurosurgery robot has been tested so far on rodents, removing tumors from their brains, and removing blood hemorrhages from the brains of pigs. Shoham expects it will be permitted to be used in clinical trials in two years or so.

In many cases of robot-assisted minimally-invasive surgery, instead of directly moving the instruments, the surgeon uses telemanipulation one or several robot hands to administer the surgery. A telemanipulator is a remote manipulator that allows the surgeon to perform the normal movements associated with the surgery. The robotic arms carry out those movements using end-effectors and manipulators to perform the actual surgery.

One advantage of using the computerized method is that the surgeon does not have to be present, leading to the possibility for remote surgery.

In 1985 a robot, the Unimation Puma 200, was used to orient a needle for a brain biopsy while under computerized tomography guidance during a neurological procedure.

Another surgical system in which Shoham was not involved is the da Vinci Surgical System, made by the US company Intuitive Surgical. Approved by the by the FDA in 2000, it is designed to assist doctors in surgery using a minimally invasive approach and is controlled by a surgeon from a console. The system is used to remove prostate glands and increasingly for cardiac valve repair and hysterectomies. It was called “da Vinci” partly because 15th-century Italian genius Leonardo da Vinci’s “Study of Human Anatomy eventually led to the design of this first-known surgical robot.

“Da Vinci works as a telemanipulation, just following what surgeon does,” noted Shoham, “but we are involved in developing robots that are not telemanipulators but have higher sense of autonomy. not just following the surgeon’s hand motion,” said Shoham. “The robot will not be just a remote manipulator, but it will proceed to be fully autonomous. There are only two companies in world approved FDA to be autonomous, and this type is more of a challenge than semi-autonomous ones.”

He is very proud that many of his students have become chief executive officers or other senior developers in other companies involving medical robots. Israelis are world leaders in medical robots, thanks to the Technion professor.

As for the concern among some people that robots will put them out of a job, Shoham stresses that they will replace low-paying, tedious jobs but create many new positions.

Just as a few decades ago, they didn’t dream that everybody would carry a mobile phone around with them instead of being dependent on a land line.

On a larger scale, the initial steps for personal robots are already being sold in the form of Siri, a virtual assistant that is part of Apple Inc.’s operating systems. The assistant uses voice queries, gesture-based control, focus-tracking and a natural-language user interface to answer questions, make recommendations and perform actions by delegating requests to a set of Internet services. The software adapts to users’ individual language usages, searches and preferences, with continuing use.

People will soon get used to the idea that everybody will have his or her own personal robot, Shoham concludes, and they will be better off. Unwilling to predict exactly where robotics will be in a decade or two, he ventured: “They definitely will be a substantial part of our lives. Combining robots with artificial intelligence and machine learning equips humanity with a strong new power. I hope it will be used wisely.”